The Q-Bic environmentally friendly packaging solution is designed to reduce logistical costs, packaging materials and food waste – and thus the carbon footprint of CPG.

86%

Product

6%

Material

8%

Air

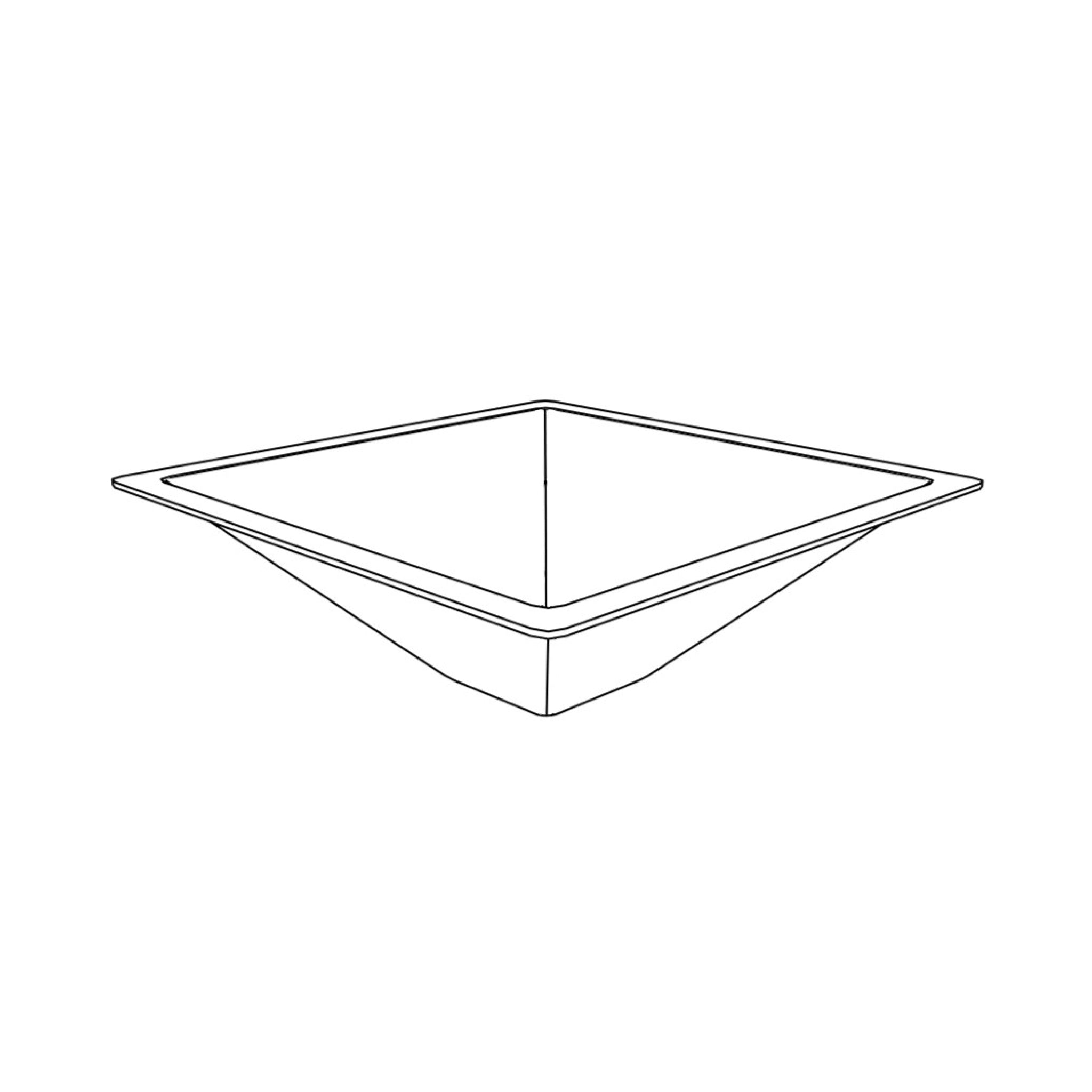

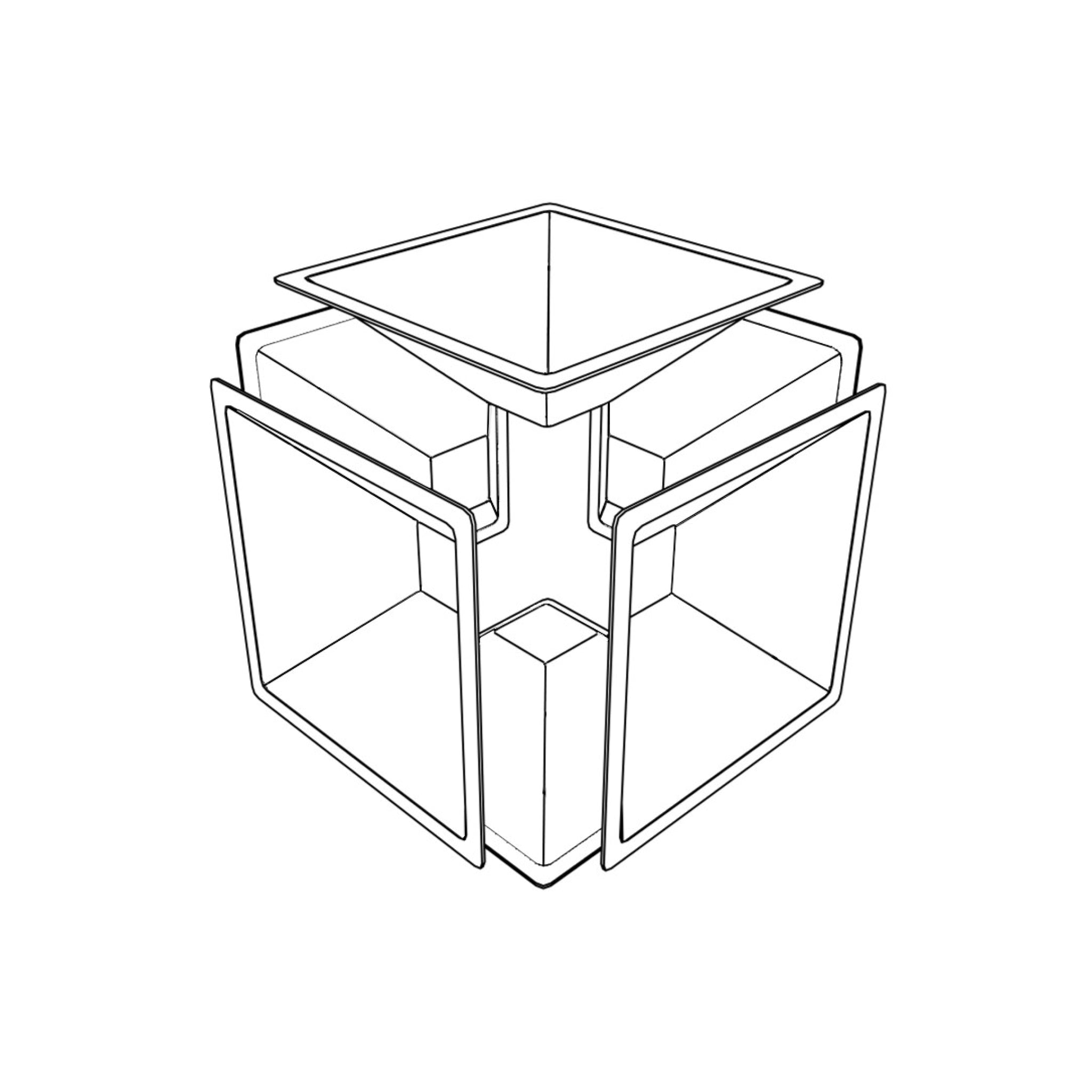

Superior Strength

Vertical forces exerted on a Q-Bic cube are displaced evenly in all axis, minimising the risks of damaged goods.

Also; when packed no internal sharp angles ever comes in contact with the top seal or lid, reducing the risk of puncture or damage.

Watch Strength DemoMaterial Neutral

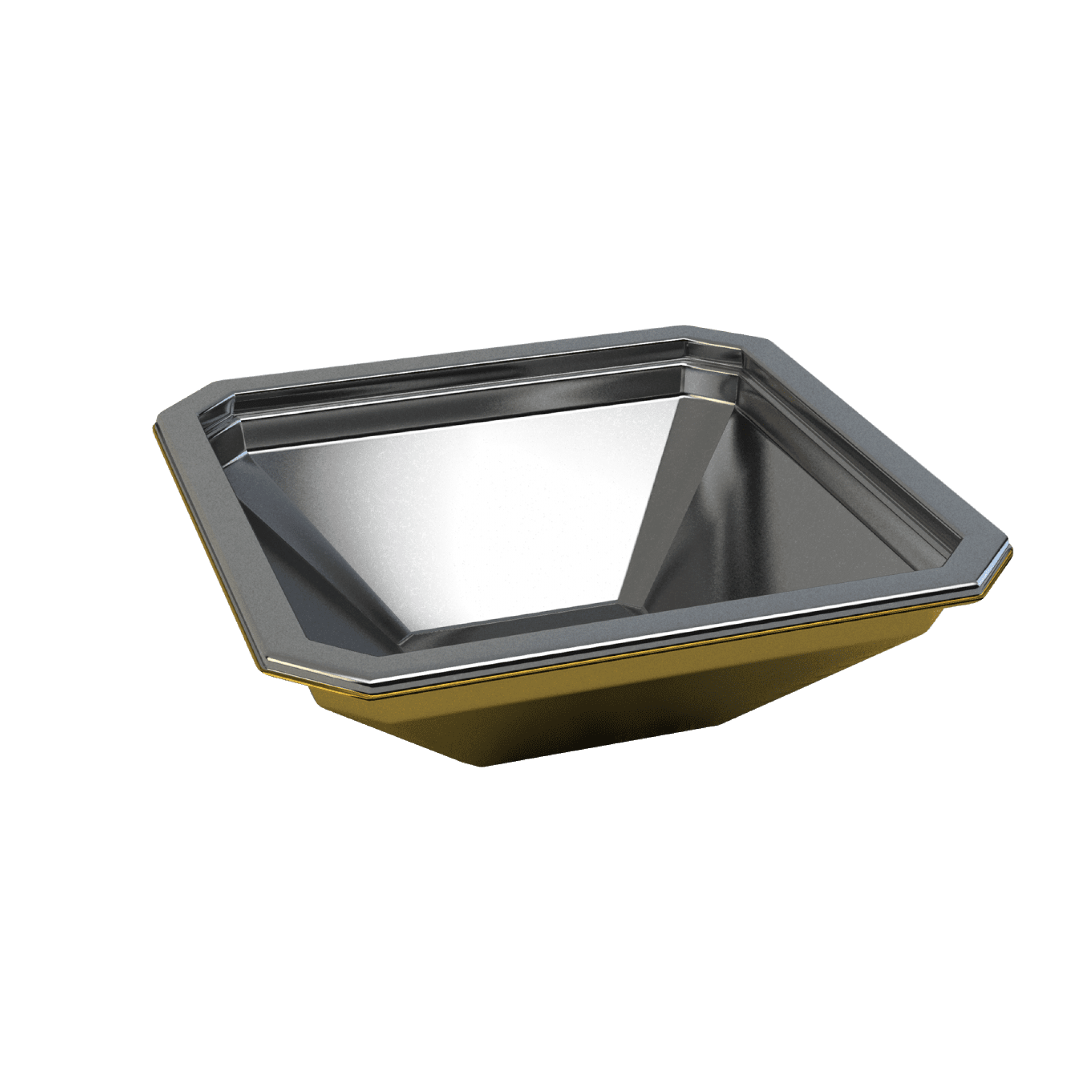

Individual Q-Bic trays can be made in a variety of tray sizes and chamber configurations.

Plastics

All PET variants; PE, PS/EPS.

Paper

PET-coted Paperboard, PP-parer hybrid, modeled paper pulp.

Alu

Wrinklewall & Smoothwall ALU-foil or stainless steel.

Other

Moulded wood sheets, glass.

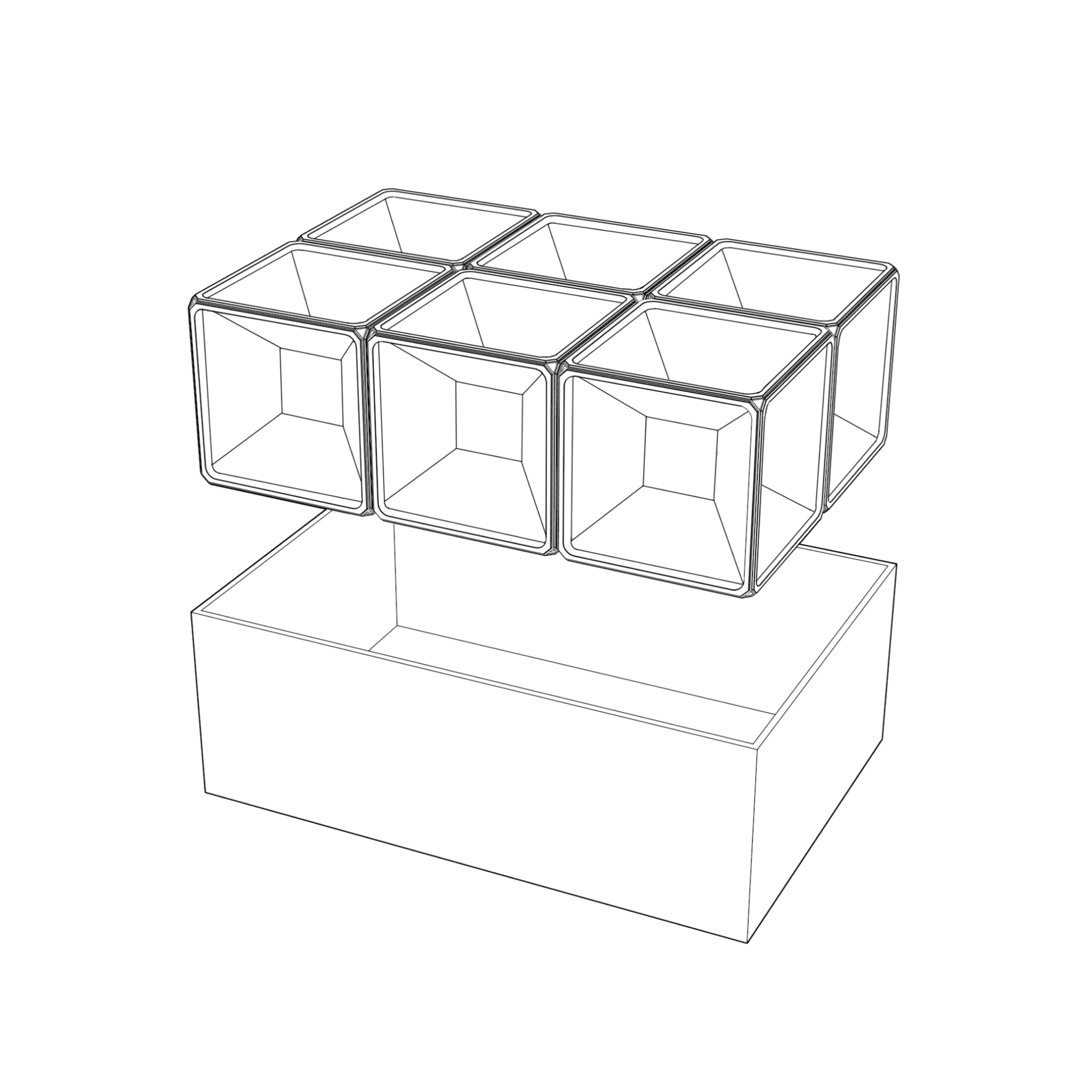

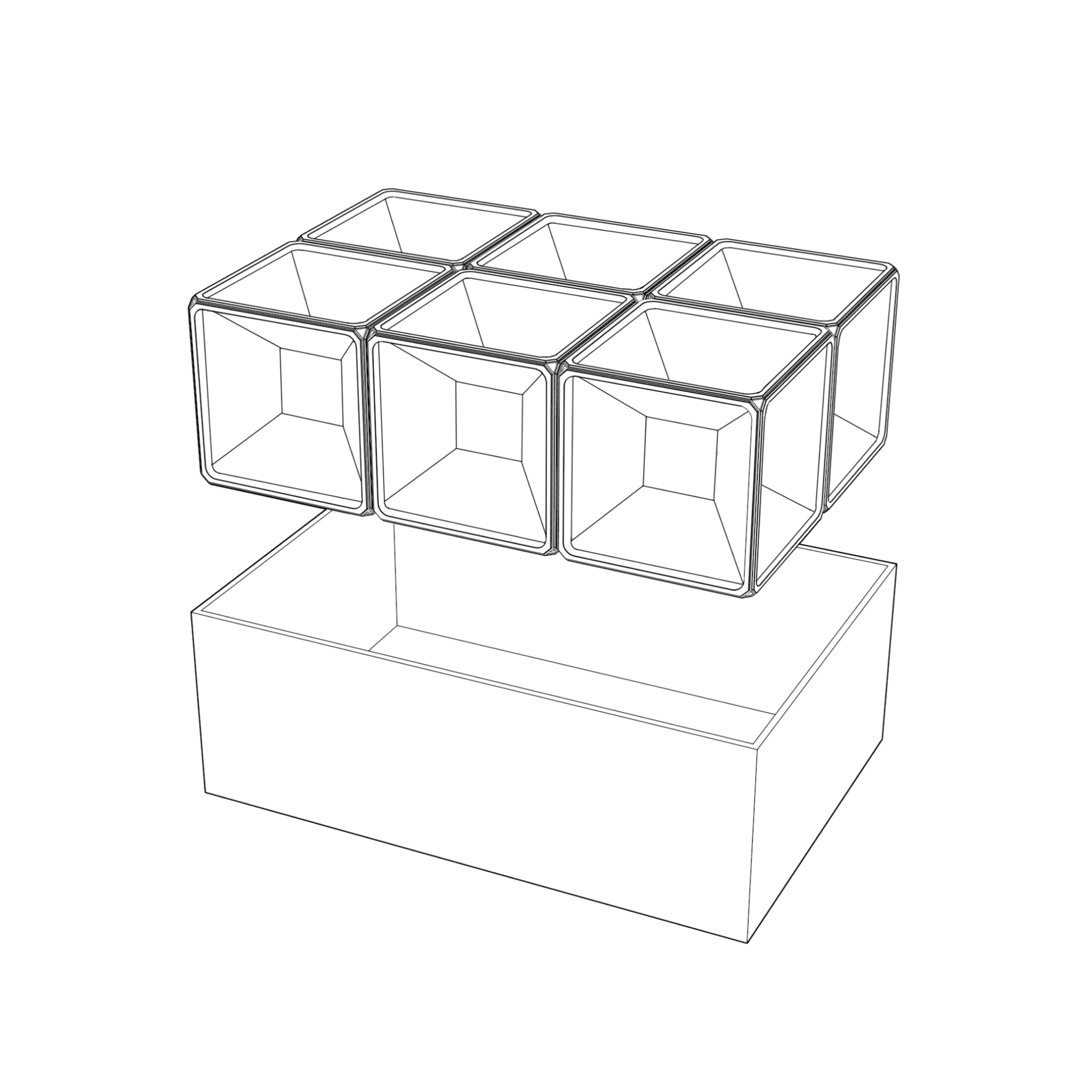

Impact

Fewer trucks and shipping containers reduce transportation needs. Less space is needed for storage in warehouses, stores, and for end consumers.

Forces displayed on a Q-Bic® cube spreads evenly in all axis makes the cube very strong and reducing the risks of damaging goods. No sharp angles ever touch the top of a single tray reducing the risk of punctuating top seals or breaking lids.

With the efficiency of Q-Bic we can have more trays in each cardboard box drastically reducing the need for cardboard Given the strength of the cube, secondary packaging is irrelevant for certain products.

Fewer pallets reduce labor cost related to (off)loading throughout the supply chain More units per box and pallet reduce handling for retailers.

Competing vs Q-Bic

Using Q-Bic trays for salads and fresh produce will ensure 2 - 2.5 x more products on the pallets. In the example shown, Q-Bic gets 2.5x the products on the pallet compared to the competing trays, with exactly the same internal volume in the three-chamber trays.

520 Competing Salad Trays

528 Q-Bic Salad Trays

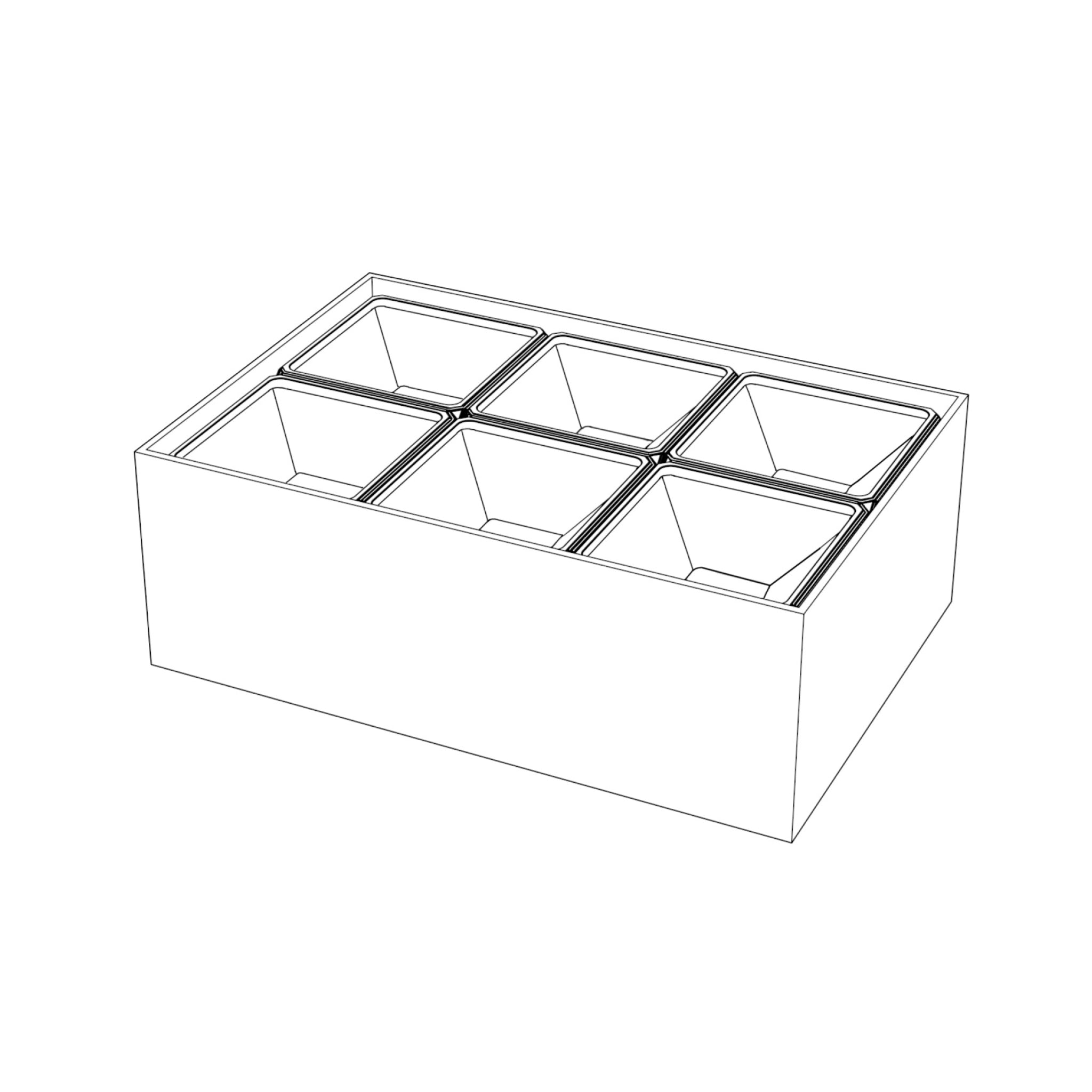

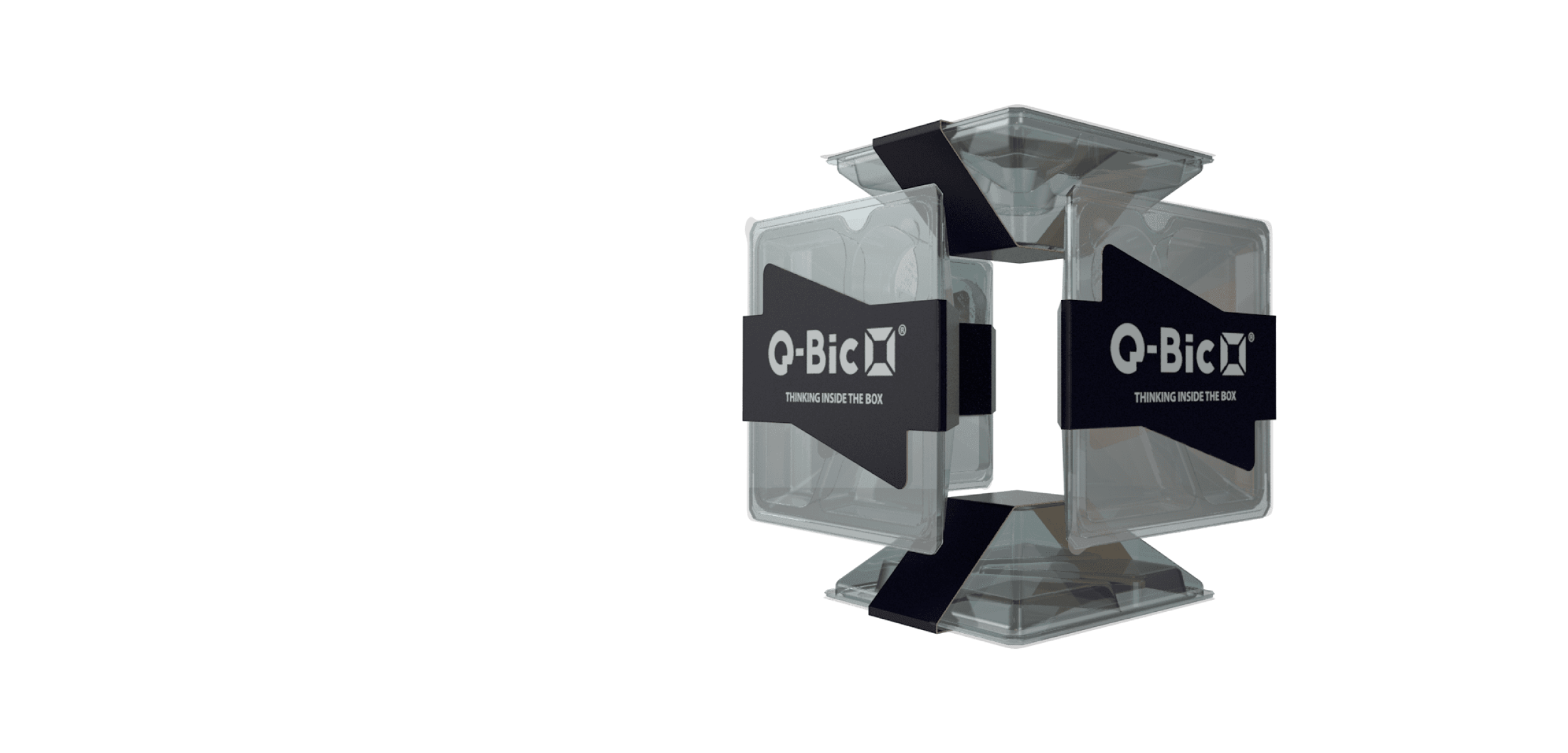

Thinking Inside the Box

Q-Bic is a new environmentally friendly packaging concept, designed to reduce carbon emissions, packaging material, and logistical costs.

Application

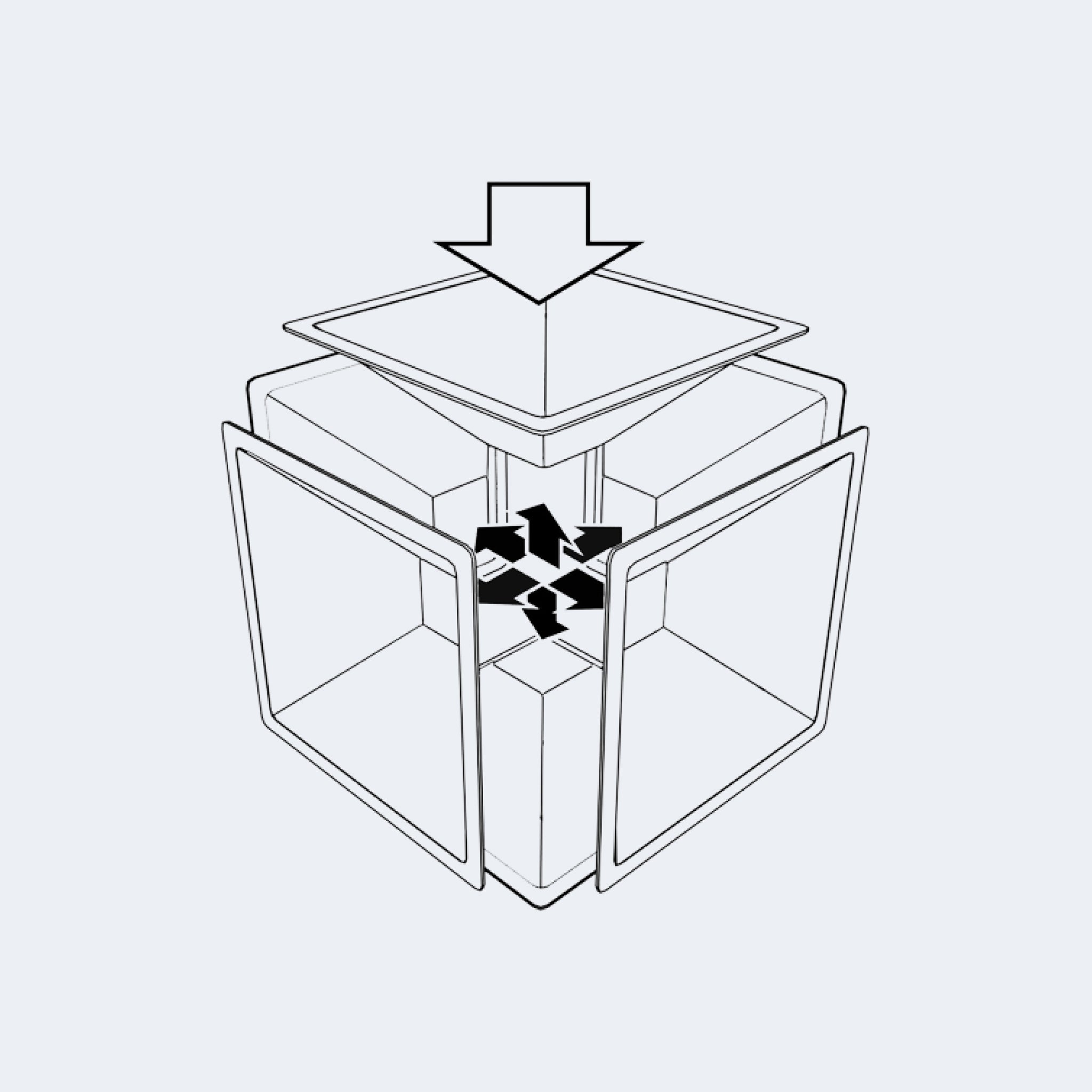

Superior Strength

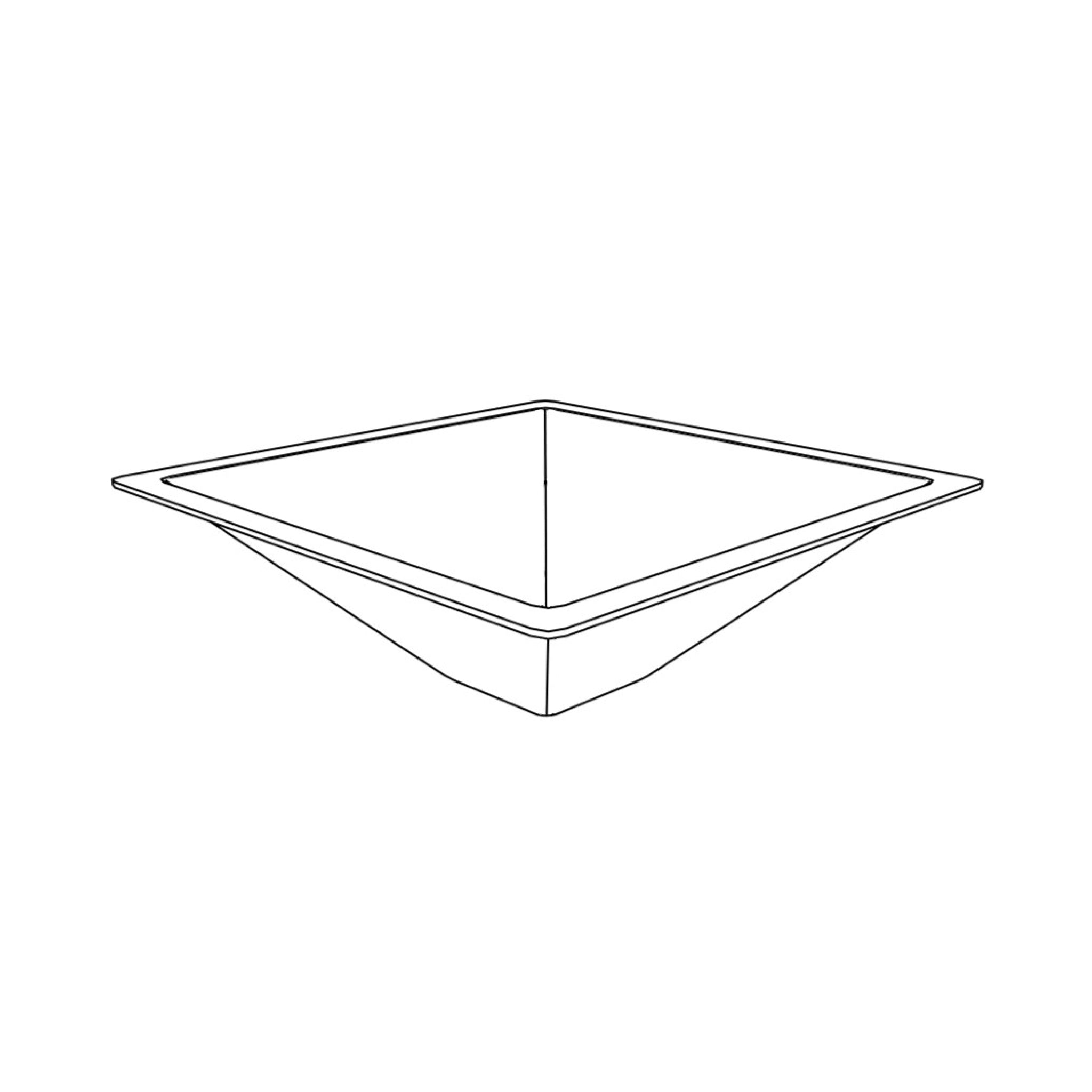

The cube can withstand more pressure than any single packaging unit could on its own. Exert vertical force on the box or container in which the six trays are placed and the load is displaced outward in all six directions, thanks to each individual tray’s 45-degree angle and wedge-like shape.

Unique Shape

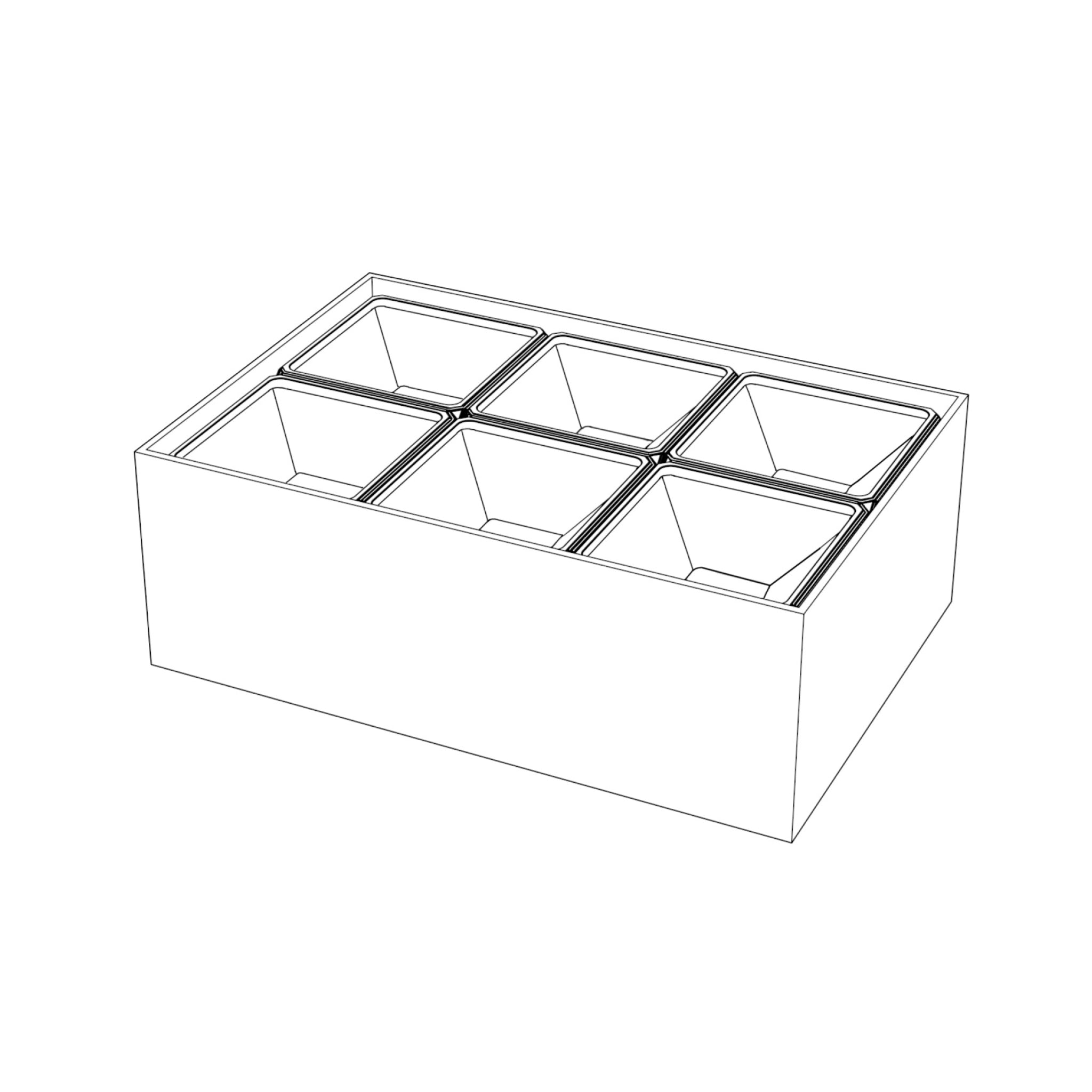

Q-Bic is comprised of six pyramid-shaped trays. The smart design allows for exceptional use of volume:

- 86% Product

- 6% Packaging Material

- 8% Air

Material Neutral

Individual Q-Bic trays come in a variety of tray sizes and chamber configurations. One thing that always remains the same is the unique pyramid shape with a 45 degree angle on the side walls.

Q-Bic trays can be made in all materials: Plastics, paper, alu, wood, biomaterial & more.

Request Samples

Use this text to share information about your brand with your customers. Describe a product, share announcements, or welcome customers to your store.